-

Design - CAD/CAM - Consulting

-

CNC Training - Process Improvement

-

Precision Machining - Laser Cutting & Engraving

-

Reverse Engineering - Rapid Prototypes

-

3D Printing - CNC Routing

Customer oriented, fast-turnaround, superior results. From design to manufacturing.

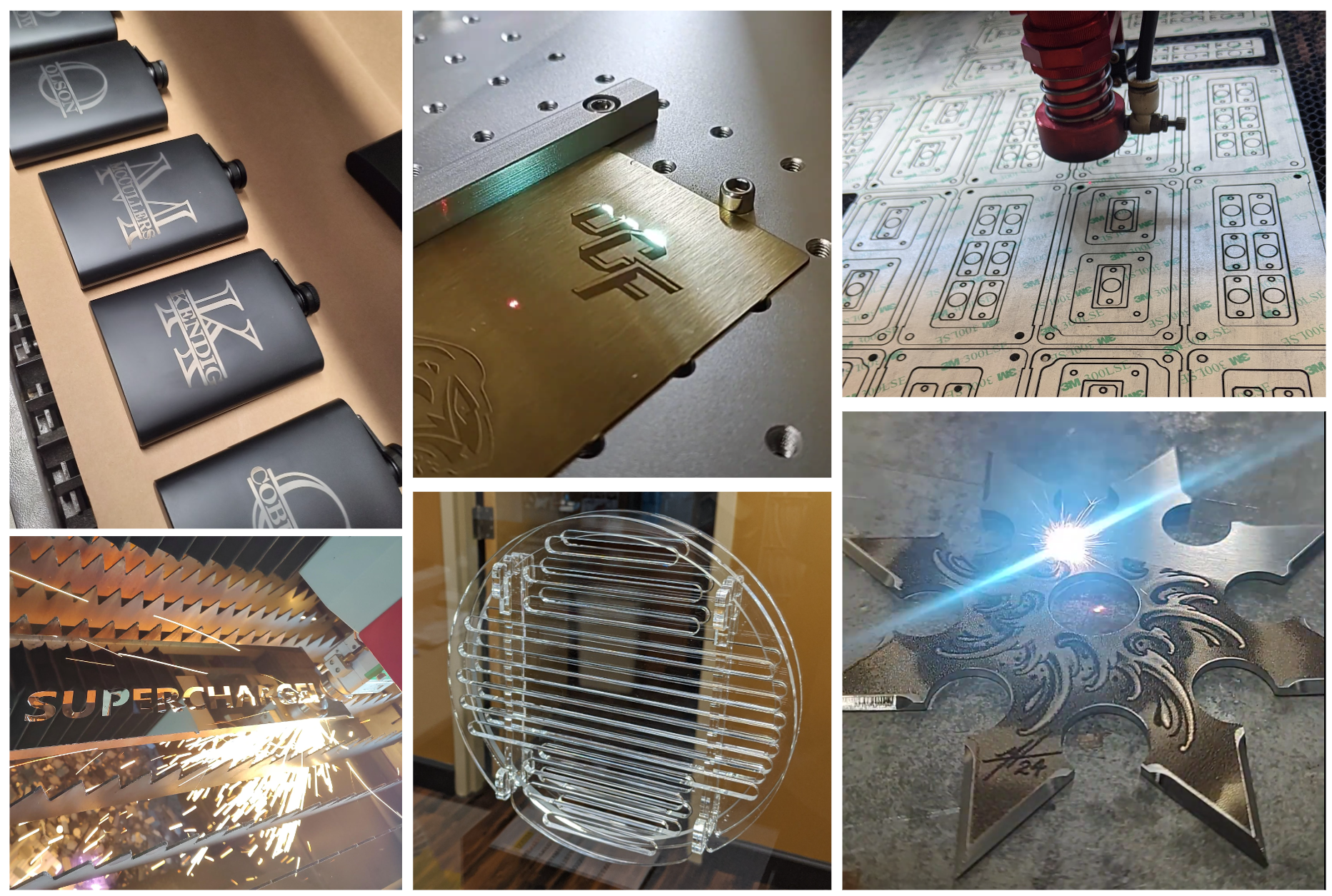

If it can be cut, We can cut it

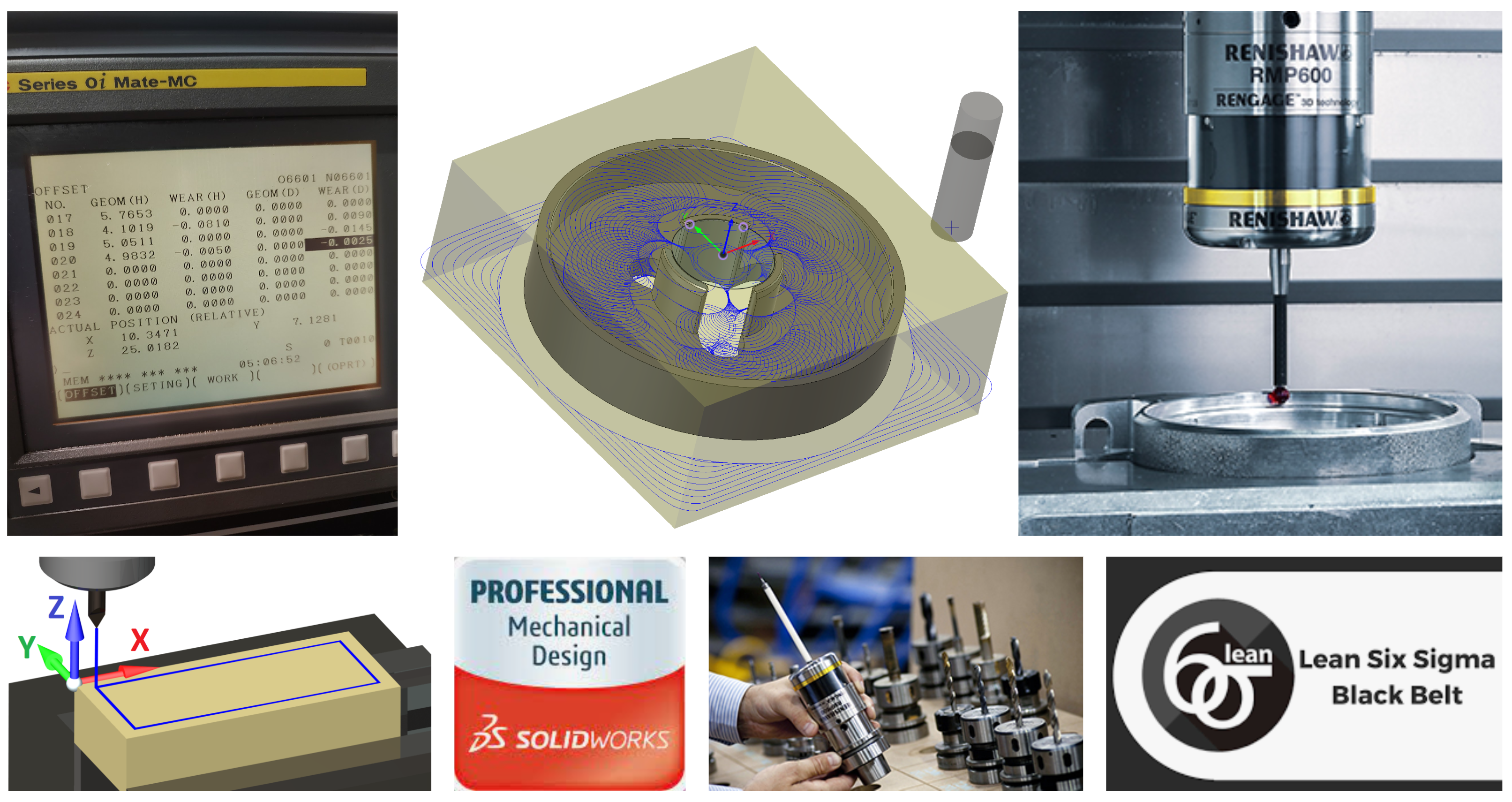

Process Development & Improvement / CNC Training

Great things happen when you work SMARTER and HARDER. We help our clients run faster, more parts per cycle, and with less scrap, OR get setup from the ground up. Whether you struggle with tooling selection, programming challenging features, long cycle times, inconsistent workholding, or designing for…

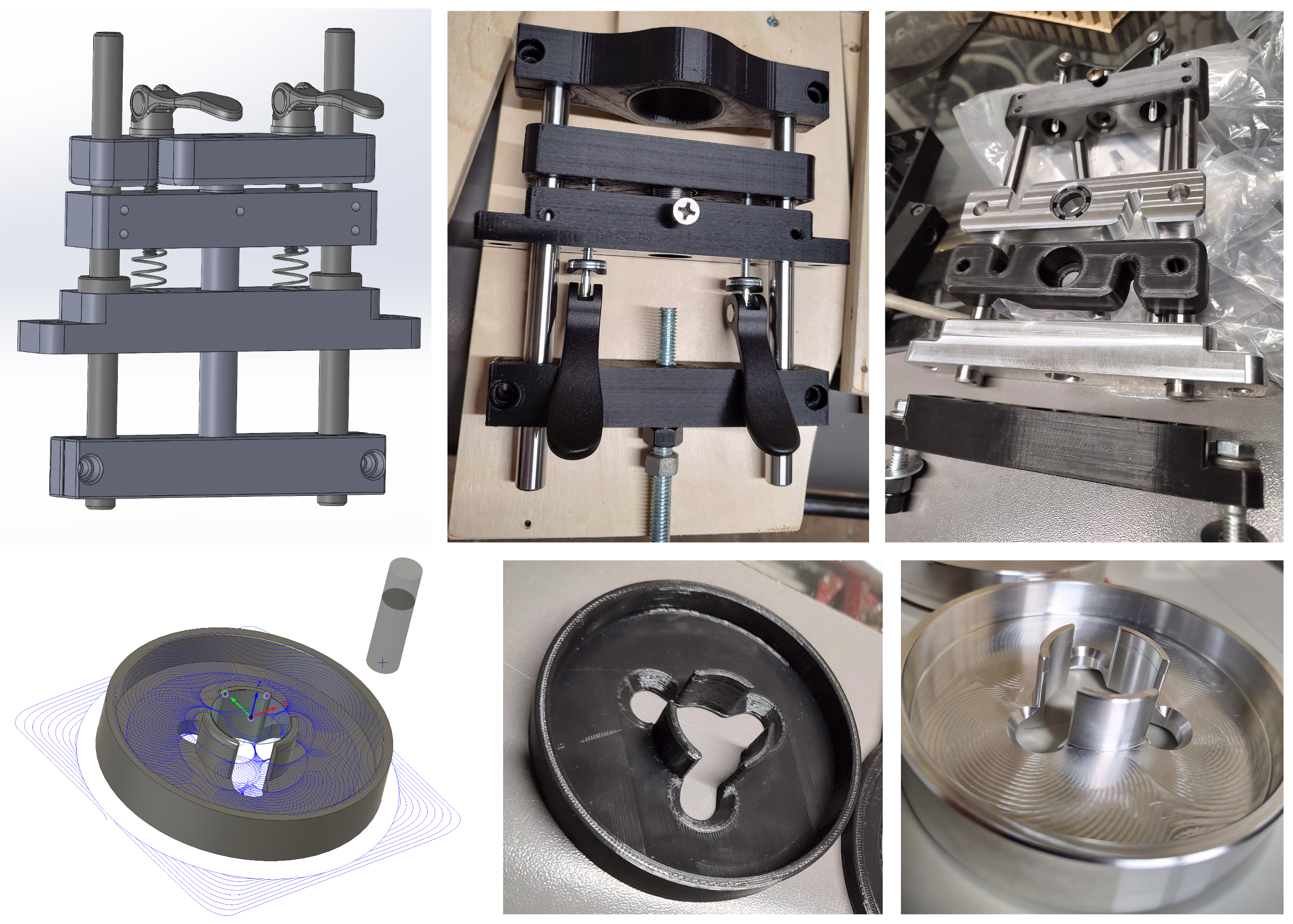

Product Design & CAD/CAM

We design and program! from your idea, napkin sketch, broken parts, legacy blueprints or CAD files. We can also provide remote or on-site CAM programming solutions. Already have a design? We can improve designs to lower manufacturing costs. Unlike many design houses, we have much more than just CAD…

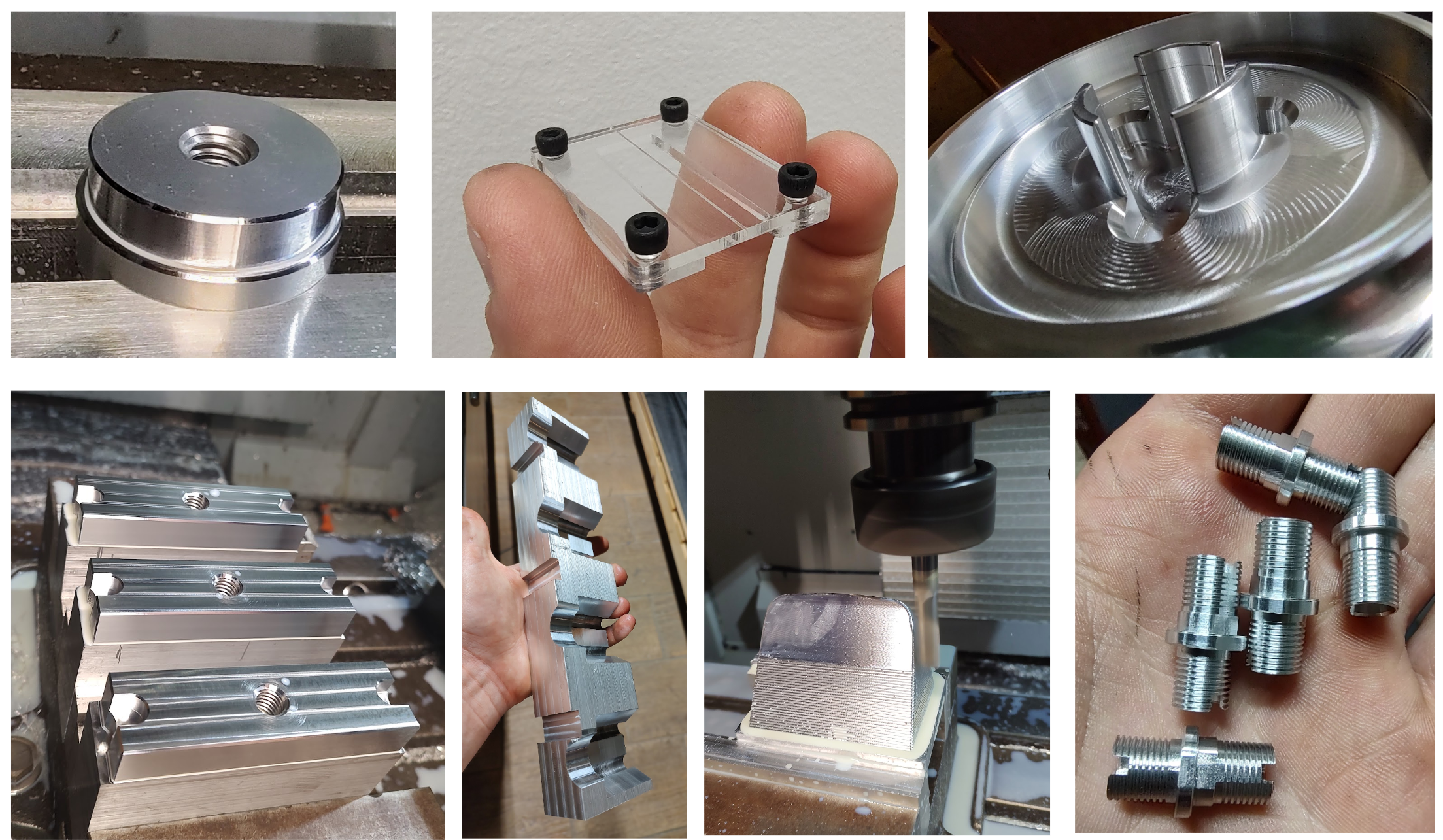

CNC Machining

We offer customer-oriented, precision parts, fast! We can cut metal, plastic and composites to your specification. Milling is our specialty; 1 part or 1000’s, prototypes or blanket PO production. Don’t have models or drawings? We can assist in development. Contact us today.

Laser Cutting / Engraving

We can laser cut your design, artwork or product! What can we cut? The material type determines what laser will be required to cut your part. We have both fiber & CO2 lasers to cut nearly all materials - if it can be cut, we can cut it! Plastics (Acrylic, Polycarbonate, ABS, Delrin, HDPE, PVC, Starboard,…

3D Printing & Rapid Prototyping

We can have parts in your hands FAST! Revisions of your product can be iterated quickly, with low cost filaments until a final design is achieved. Then, depending on the application, prototypes can be printed in one several material types such as ABS, Nylon or Carbon Fiber reinforced filaments; OR we can…

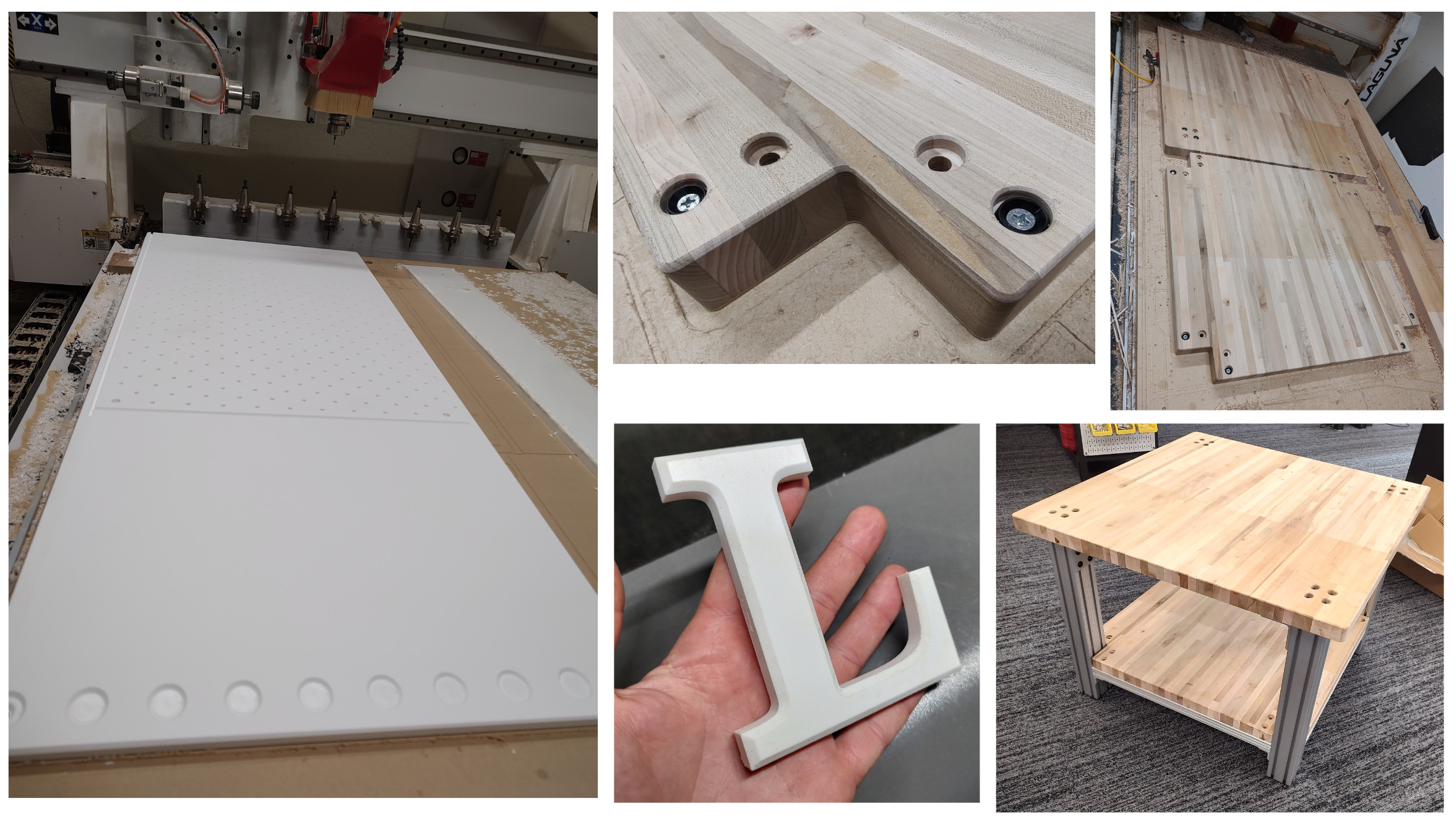

CNC Routing

Similar to machining, our advanced CNC router can handle complex geometries, but on a much larger scale or give the ability to nest many shapes in one setup to reduce overall costs. This process can handle dusty composites, fiberglass, plastics, or woods that one not suited for machining centers. Don’t…